Laser Sheet Cutting

Laser sheet cutting is a modern and extremely precise metalworking method that combines accuracy, high speed, and wide application possibilities. Laser technology allows for cutting even highly complex shapes and fine details with exceptional precision that cannot be achieved using traditional methods. By minimizing material waste and reducing the need for additional machining, this process is not only efficient but also cost-effective. Laser cutting of steel is widely used across multiple industries – from manufacturing and construction to advertising and decorative design. We invite you to explore our offer and discover the advantages of professional laser sheet cutting.

Our Offer – More Than Just Laser Cutting

We offer comprehensive metalworking services. We perform precise laser cutting of the following materials:

Material Maximum cutting thickness Mild steel approx. 25 mm (12 mm with smooth edge; up to 25 mm using WACS support system) Stainless steel approx. 13–15 mm (with optional GAX-MIX cutting system) Aluminium approx. 12–13 mm (with optional Silky-Cut system) Brass approx. 8 mm Copper approx. 6 mm Corten steel approx. 15 mm Hardox wear plate approx. 12 mm- stainless steel cutting – high-quality stainless, acid-resistant, ferritic, and duplex steels;

- aluminium laser cutting – an ideal solution for projects requiring lightness and strength;

- brass laser cutting – for precise and decorative elements;

- copper laser cutting – perfect for electrical conductivity and visual appeal;

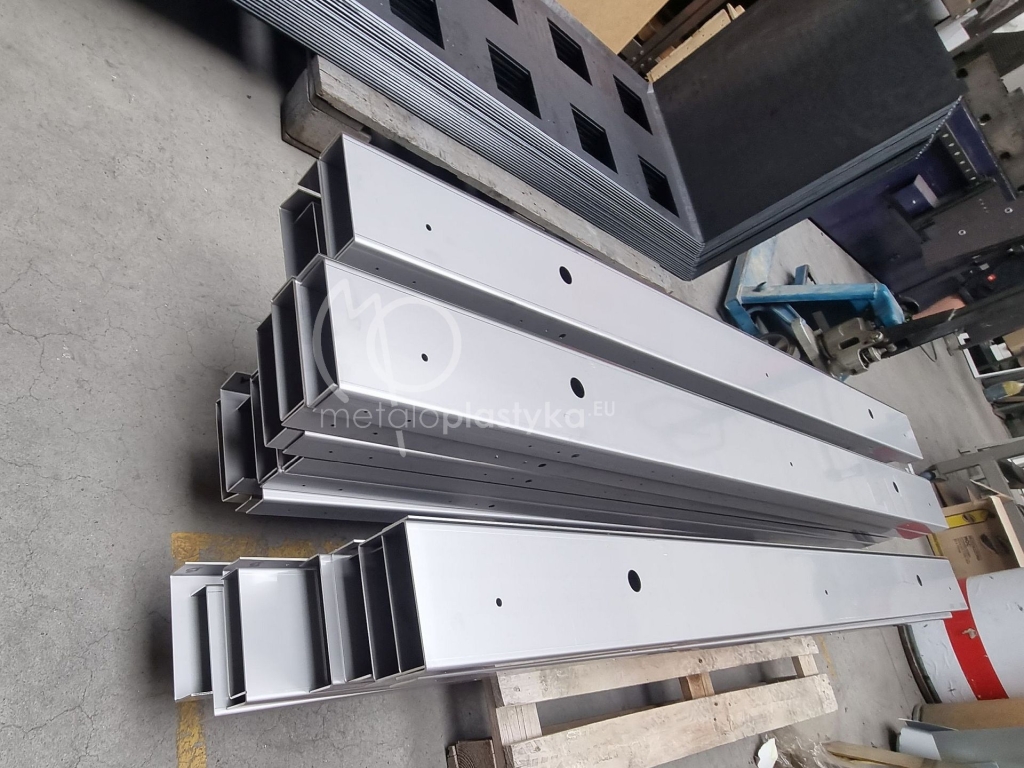

- sheet bending – complements the laser cutting process, allowing the creation of finished, functional components with precise angles and shapes.

Each of these laser cutting services is carried out with the utmost precision using modern technology, guaranteeing product quality and durability. In addition to laser steel cutting, our clients can rely on comprehensive support, including technical consulting and service adjustments to specific project needs.

Laser Sheet Cutting – Precision Technology

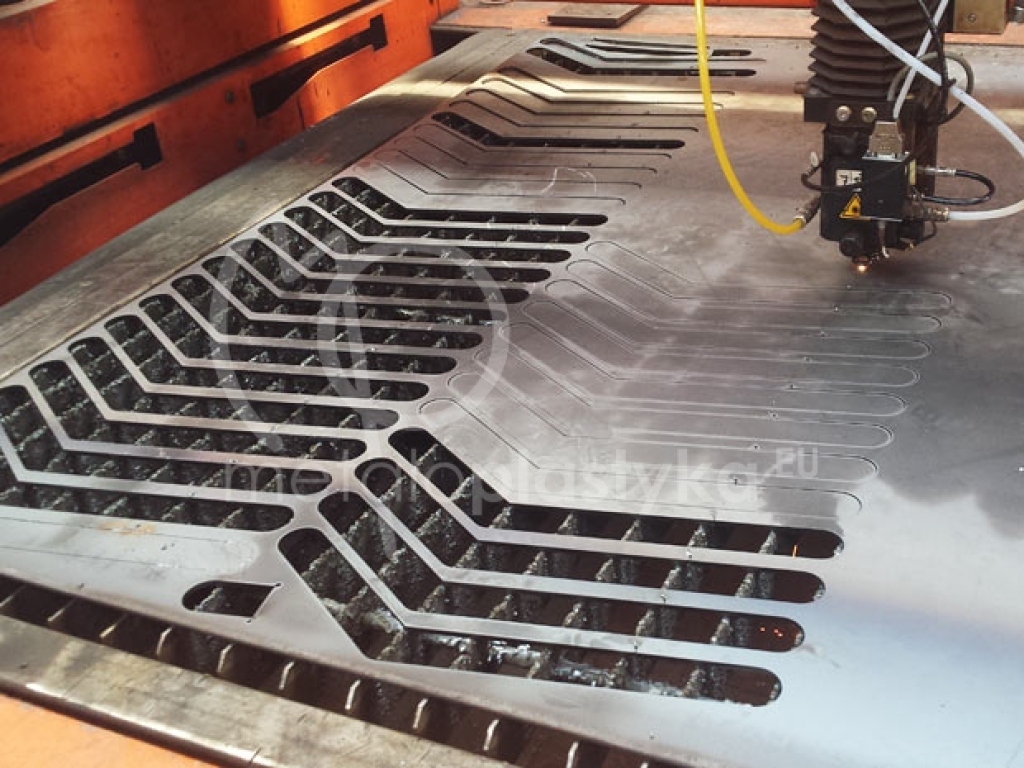

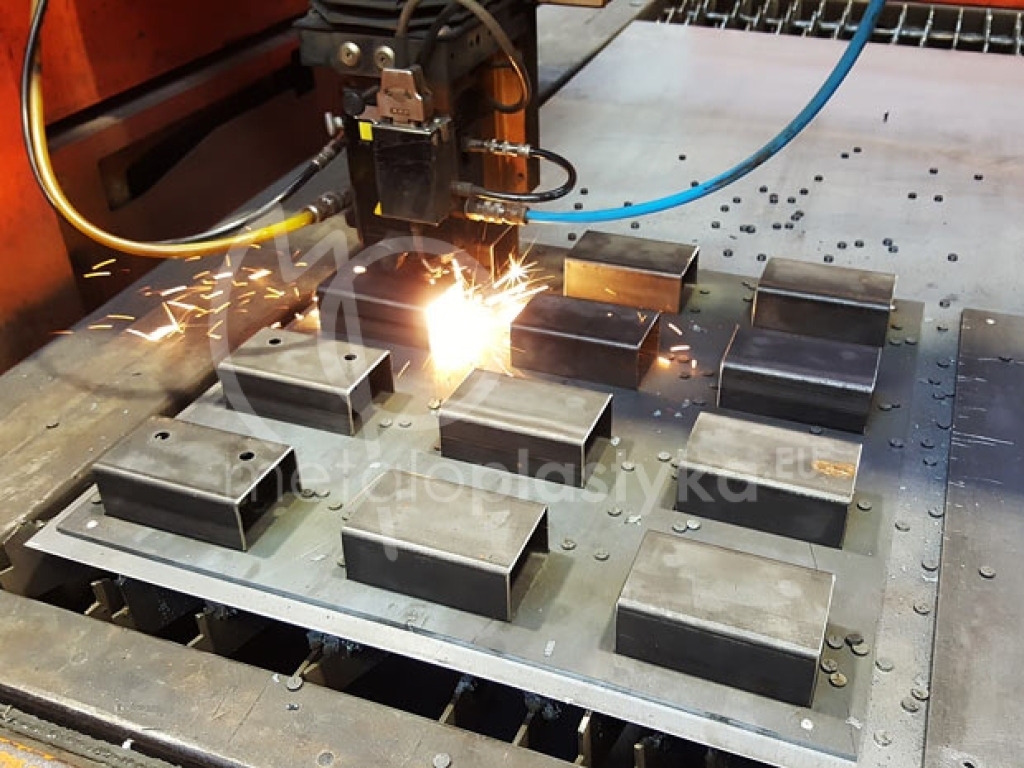

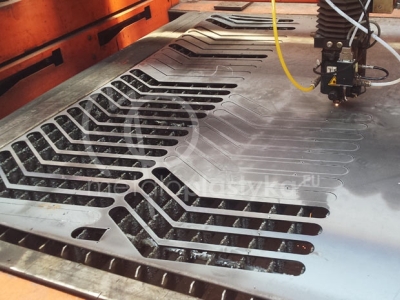

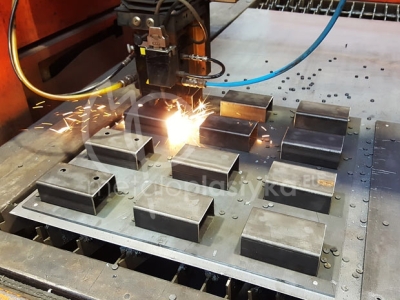

Laser sheet cutting is an advanced technology that focuses a precise laser beam on the surface of the material, causing localized melting or vaporization. In our company, we use the AMADA ENSIS 3015AJ laser cutter – a modern machine that ensures:

- high precision and repeatability – essential for serial production and complex projects where exact cutting accuracy is required;

- versatility – capable of cutting stainless steel, aluminium, brass, and many other metals;

- minimal material waste – achieved through optimal laser beam efficiency and nesting strategies;

- advanced Fiber technology – delivering faster and more efficient sheet cutting compared to conventional methods;

- excellent cutting-edge quality – eliminating the need for additional finishing operations.

Laser steel cutting with the AMADA ENSIS 3015AJ combines innovation and reliability, meeting the highest precision standards in modern metal fabrication.

Applications of Laser Sheet Cutting

Laser sheet cutting has a wide range of industrial applications and is commonly used in:

- the automotive industry – where precision and quality are critical for vehicle safety;

- construction – where laser-cut stainless steel ensures durable structures;

- furniture manufacturing – offering aesthetic and dimensionally accurate components;

- aerospace – where every detail must meet the highest quality standards.

Thanks to its versatility, laser cutting is an ideal solution for both small and large enterprises. The process adapts to the needs of any industry, ensuring precision and efficiency. Combined with advanced technologies such as WACS and SILKY-CUT, it guarantees perfect finishing and the highest quality of execution.

Advantages of Laser Cutting Technology

Laser sheet cutting brings numerous advantages, including:

- high precision and clean cutting edges;

- minimal material loss;

- short lead times.

Furthermore, Fiber laser technology allows for cutting sheets and other materials of various thicknesses – from thin sheets to heavy plates. Laser cutting of steel and other materials also helps optimize costs by reducing waste and minimizing post-processing time. All this makes laser cutting one of the most efficient methods on the market.

Why Choose Our Laser Cutting Services?

Our company, Metaloplastyka, stands out for its extensive experience in laser cutting of steel and numerous completed projects. We use advanced technologies, including:

- WACS – for cutting thick steel sections;

- SILKY-CUT – for smooth aluminium edges.

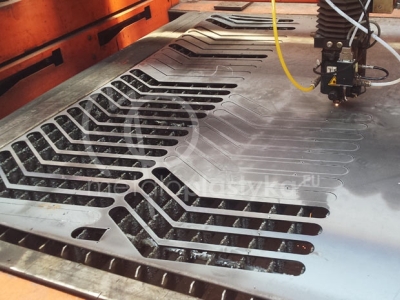

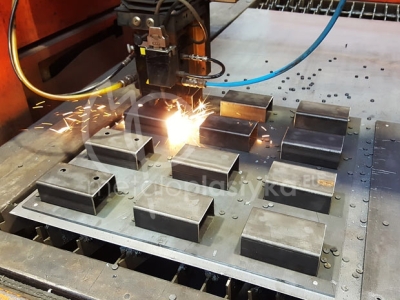

We invite you to visit our gallery, where you can see examples of our laser cutting work. Our laser ensures fast and precise cutting of materials of various thicknesses, guaranteeing optimal quality for every project. Working with us means on-time delivery, precision, and an individual approach to each order.

Our Offer – More Than Just Laser Cutting

We offer a full range of metal processing services. We provide cutting of stainless steel and various materials, as well as additional complementary operations, including:

- aluminium laser cutting – ideal for projects requiring light and durable elements;

- brass laser cutting – perfect for decorative and precision components;

- copper laser cutting – excellent for conductivity and refined aesthetics;

- sheet bending – complements laser cutting, enabling the creation of functional, precisely shaped parts.

Each laser cutting service is performed with the highest attention to detail using advanced technologies, ensuring durability and top quality. Beyond laser steel cutting, our clients can expect full support, including technical advice and customized project solutions.

Automation and Repeatability – A New Standard in Sheet Metal Cutting

Thanks to advanced CNC (Computer Numerical Control) systems, laser cutting of stainless steel and other metals ensures not only the highest precision but also full repeatability, even in large-scale production runs. This means that every element – regardless of batch size – maintains identical parameters and consistent quality. Such solutions are particularly valued in modern industry, where both speed and accuracy matter. Combined with modern Fiber technology and professional service, laser cutting of metals becomes not only technically efficient but also cost-effective. These technologies enable us to deliver the highest quality laser cutting services, regardless of project complexity.

Contact Us

For laser cutting pricing and additional information, please contact us by phone, email, or via the contact form on our website. Our office and production facility, where laser steel cutting is performed, are conveniently located in Błonie, near National Road No. 94.

- Address: Błonie, ul. Produkcyjna 1, 55-330 Miękinia, Poland

- Phone: +48 71 794 59 34

- E-mail: biuro@metaloplastyka.eu

- Working hours: Monday – Friday, 7:00 AM – 3:00 PM

Our team will be happy to answer any questions about laser steel cutting and assist you with your project. Every detail of cooperation is tailored to individual client needs to achieve optimal results. We also encourage you to visit our website, where you can find more information about our services and completed projects. The price for laser sheet cutting is determined individually, depending on project requirements and material specifications, ensuring full flexibility and cost optimization.