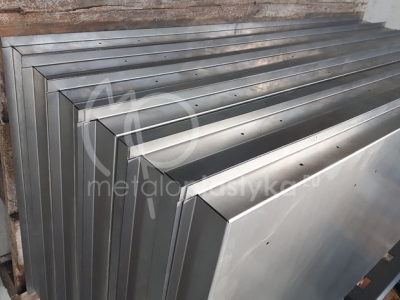

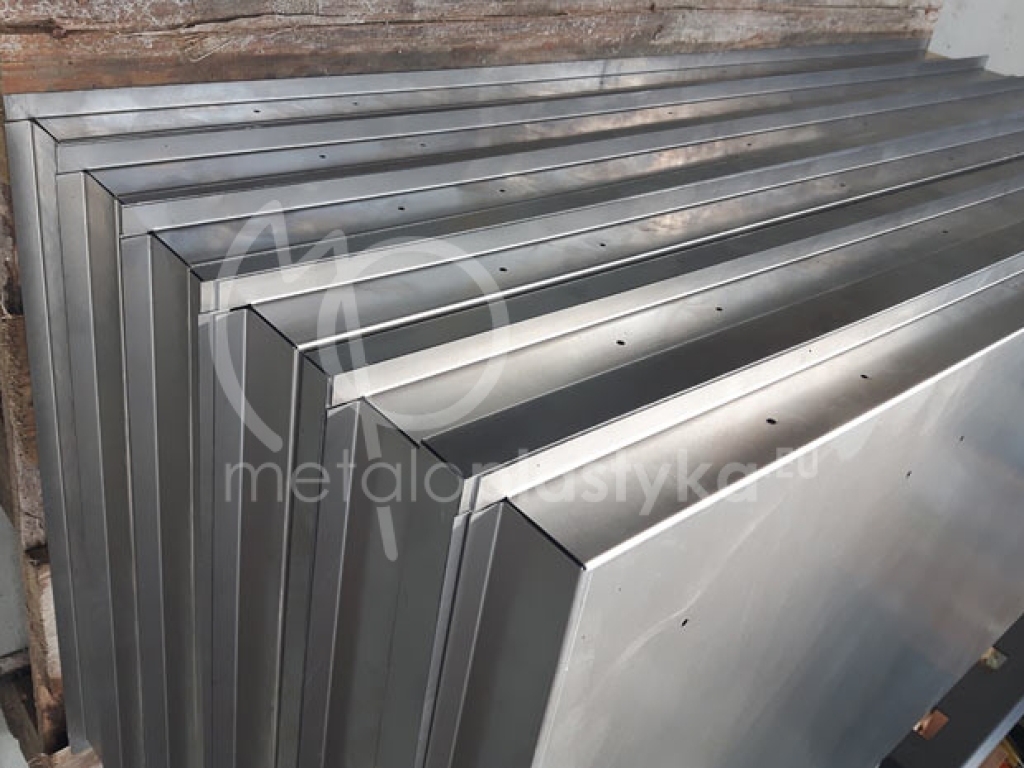

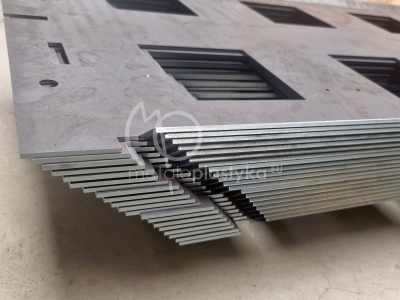

Sheet Metal Bending with a Press Brake

Bending sheet metal with a press brake is a process that combines advanced technology with precise metalworking. It enables the creation of components of various shapes and sizes, ideal for industrial and manufacturing applications. The use of modern machines such as the Beyeler Xpert 150 press brake guarantees top quality and precision, tailored to individual requirements. Explore our offer and discover the possibilities we provide in the field of sheet metal bending.

What do we offer in sheet metal bending?

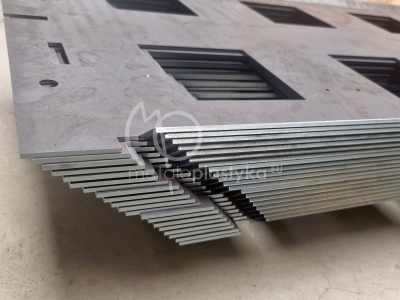

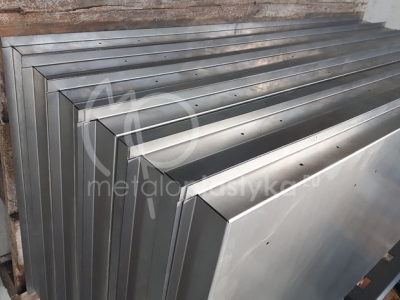

Sheet metal bending with a press brake includes a wide range of technological possibilities, allowing for precise forming of sheet metal into the desired shapes. Our machines are capable of processing a variety of materials. Our services include, among others:

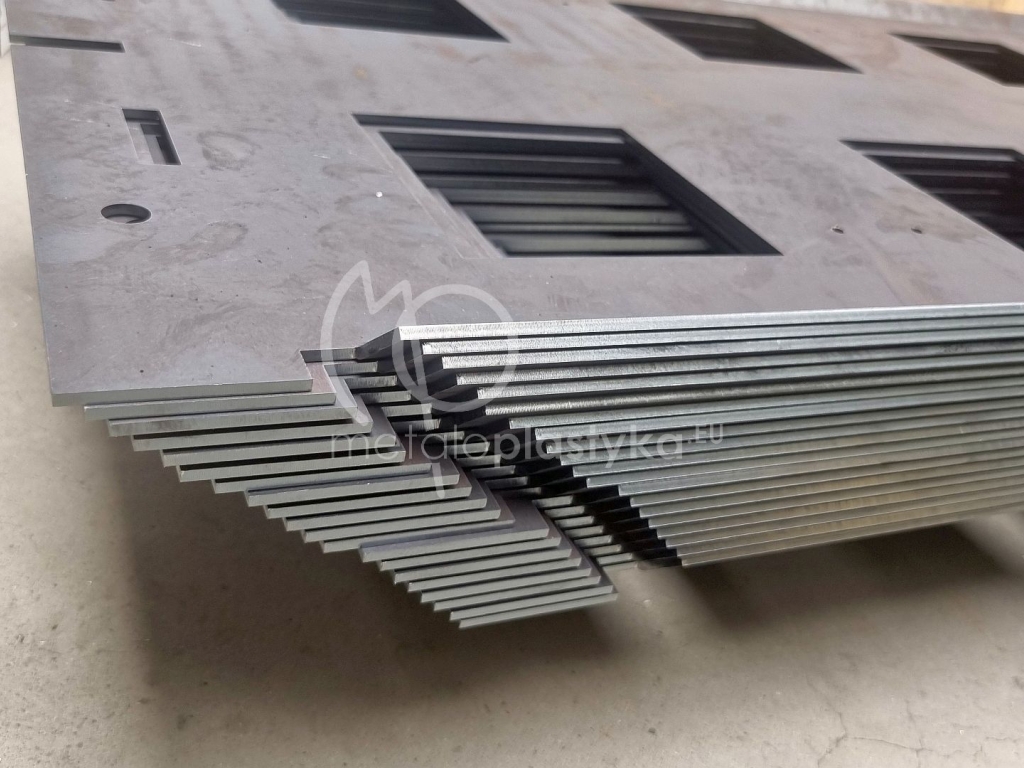

- steel sheet bending with a press brake – precise forming in accordance with project specifications;

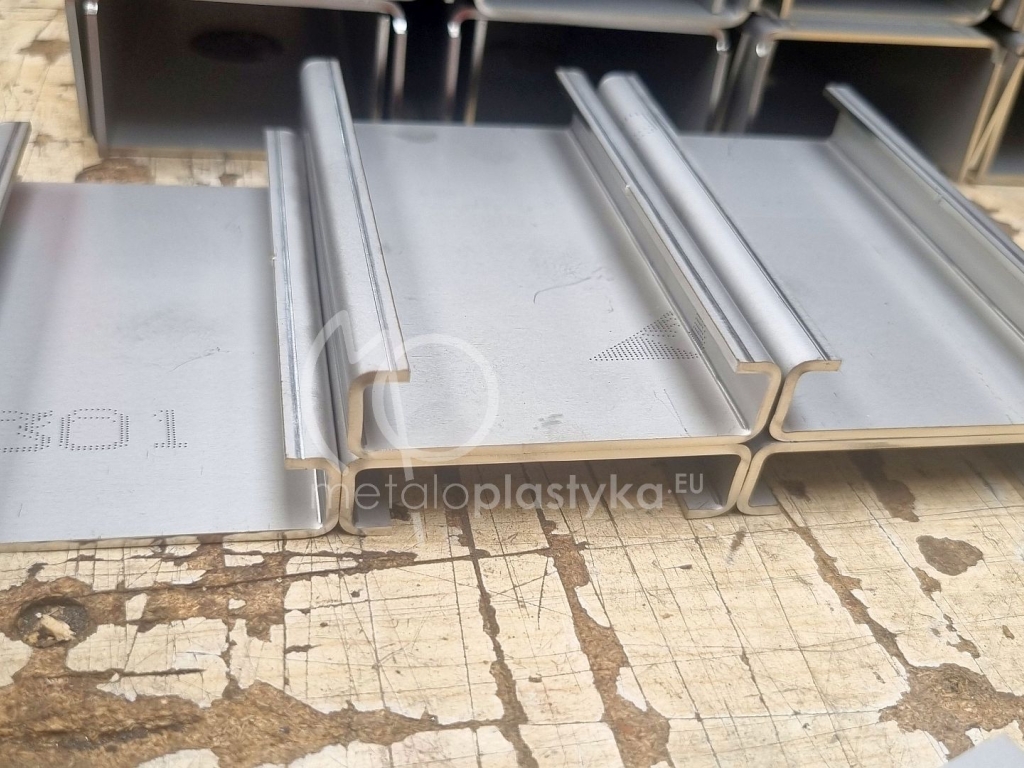

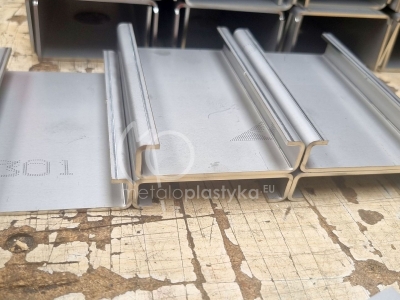

- aluminum bending – ideal for lightweight structures and elements with high aesthetic value;

- stainless steel bending – performed using a press brake, enabling accurate forming of sheets into specific shapes and angles. The bending capacity depends on the machine parameters such as tonnage, as well as the maximum length and thickness of the processed material;

- brass sheet bending – brass, as a copper-zinc alloy, features good plasticity, which allows for precise shaping of details without the risk of cracking. Bending is carried out with controlled press pressure to prevent deformation and material stress;

- copper sheet bending – copper is a soft metal that requires precise adjustment of bending parameters due to its tendency to deform and spring back. The process is performed with optimized pressure and bending radius;

- galvanized steel bending – galvanized sheets are coated with a zinc layer that protects them from corrosion, so bending must be done carefully without damaging this layer. Our press brake enables forming while maintaining the integrity of the protective coating.

Each bending operation is performed according to the highest technical standards, ensuring repeatability and precision in serial production.

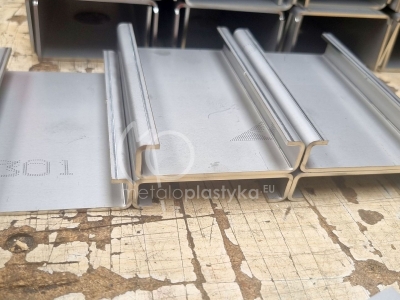

The sheet metal bending process and our machine’s capabilities

Bending on our press brake is performed using the modern Beyeler Xpert 150 machine. The process involves several stages, from material preparation to final forming. A key part is the precise adjustment of parameters such as pressure, bending angle, and speed. Our press brake features:

- maximum pressure up to 150 tons – allows for efficient bending of thicker sheets;

- bending length up to 3100 mm – enables processing of large components;

- CNC control – ensures high accuracy and repeatability in serial production.

The bending process is continuously monitored, minimizing errors and ensuring perfect repeatability.

What makes our sheet metal bending equipment stand out?

Our press brake is an advanced tool that combines technology with precision. Equipped with a dynamic deflection compensation system and hydraulic tool clamping, it ensures excellent results. Key features include:

- AKAS laser safety system – ensures operator safety and precise bending accuracy;

- high positioning speed – allows for fast and efficient forming;

- hydraulic tool clamping – enables quick tool changes, reducing production time.

Equipment of this class guarantees top quality, especially for complex projects requiring the highest precision.

How to order sheet metal bending and get a quote?

The ordering process has been simplified to make it easy and efficient. To prepare a quote, we require technical drawings (in DXF, DWG, or PDF format) and a detailed project description. The ordering steps include:

- sending technical documentation with project details;

- specifying the type of service, such as sheet bending, laser cutting, or TIG welding;

- receiving a quotation and confirming the order.

Drawings and plans for sheet metal bending should include all necessary details such as dimensions, material type, and any additional elements like welds or holes. For more complex projects, we recommend contacting us directly via email or phone to discuss the details.

Why choose our bending services?

Our company provides comprehensive metalworking services, including aluminum, steel, and other sheet metal bending. With advanced technology and a skilled team, we guarantee top quality and on-time delivery. In addition to bending, we also offer complementary services such as:

- laser cutting – precise and fast sheet metal shaping;

- TIG welding – ideal for precise and durable joints in metal structures;

- shearing – efficient cutting of materials to desired dimensions.

Sheet metal bending and additional services can be combined within a single order, enabling even the most complex projects to be completed in one place. Contact us to learn how Metaloplastyka can support your production needs.