TIG and MIG/MAG Welding Services

MIG welding is one of the most widely used metal joining methods, valued for its durability, speed, and versatility. When combined with TIG technology, it offers extensive capabilities — both for large steel structures and precise, small-scale components. This approach works perfectly for both serial production and custom-made projects, serving the industrial, construction, and artistic sectors. It enables joining of various materials with exceptional precision. If you value durability, aesthetics, and compliance with standards, you’re in the right place. Discover how we can help — explore our offer!

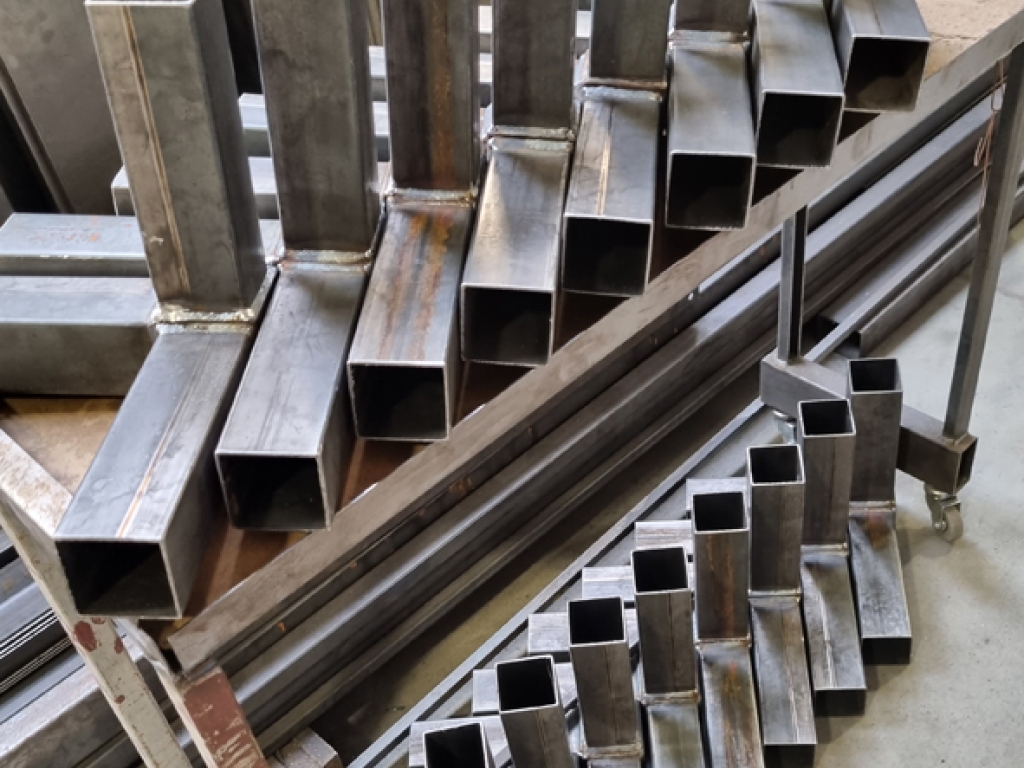

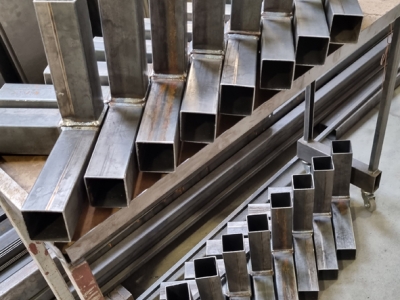

MIG Welding — Speed and Versatility

MIG welding is the ideal solution wherever efficiency and strength matter. The process is based on the automatic feeding of a wire electrode in an inert gas shield, ensuring fast and continuous operation. The main advantages of the MIG welding method include:

- high efficiency and short production time;

- the ability to weld carbon steel, stainless steel, and aluminum;

- low operating costs for large production runs.

If you need reliable performance for large steel structures, MIG welding is the right choice.

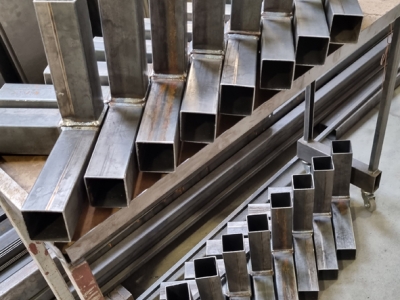

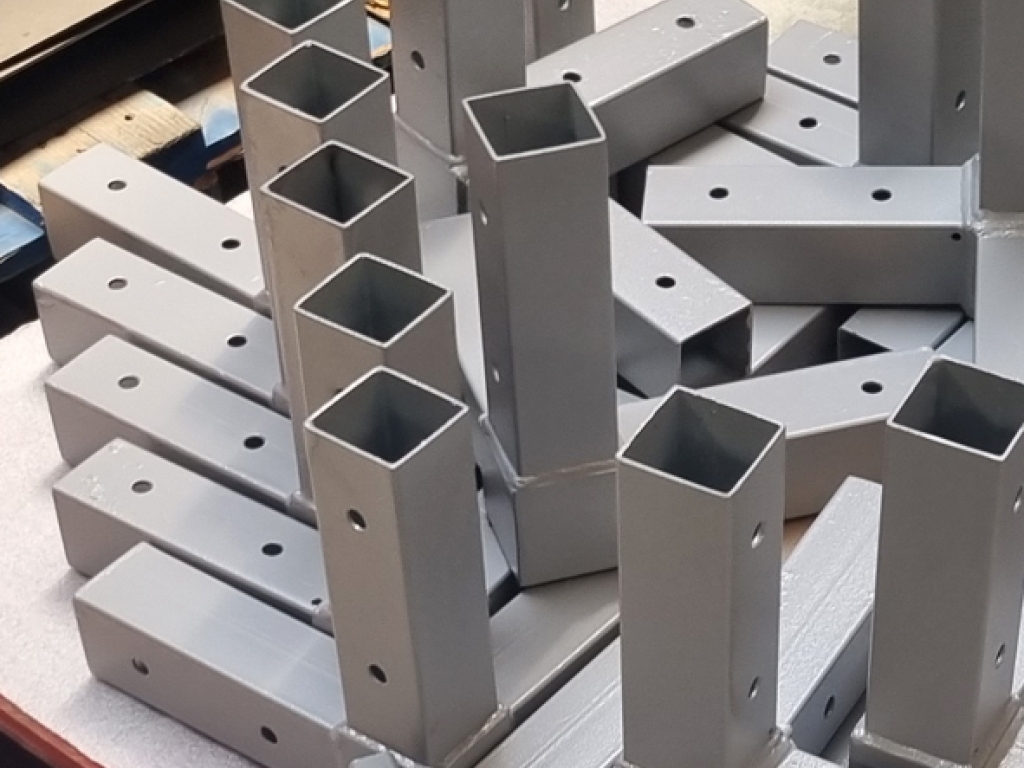

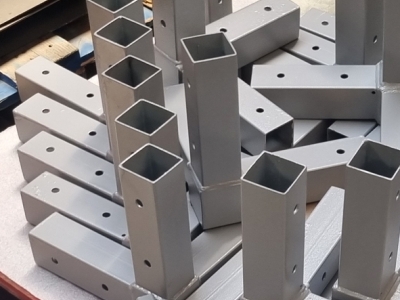

MAG Welding — Strength and Durability for Demanding Structures

MAG welding is widely used in heavy industry, construction, and steel structure manufacturing. It’s a technique that employs a consumable wire electrode in an active gas shield, providing extremely strong welds resistant to high loads and weather conditions. Therefore, it’s perfect for load-bearing structures, supports, and machine components. Using the MAG welding method ensures solid results without compromise — both in production halls and on-site installations.

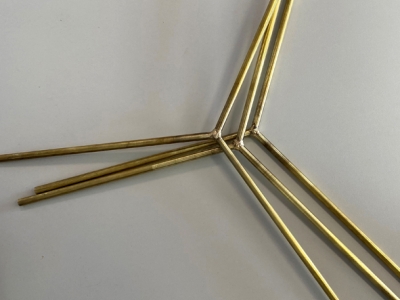

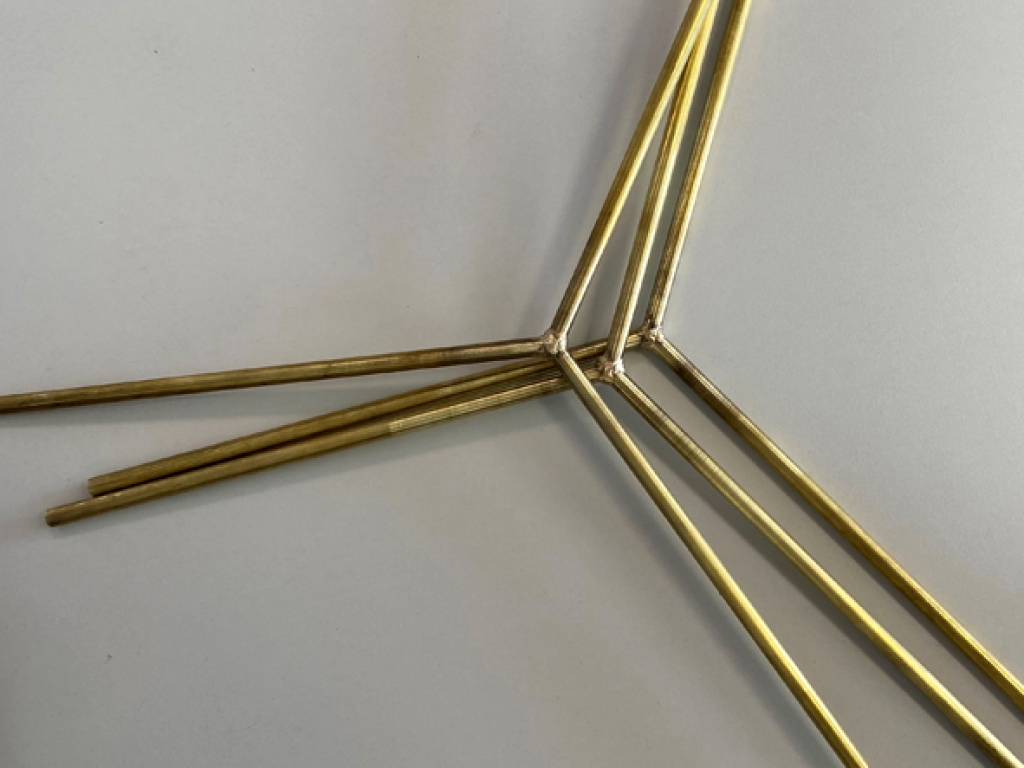

TIG Welding — Precision and Aesthetics

TIG welding is the best choice for joining thin materials that require the highest precision. Using a non-consumable tungsten electrode in an inert gas shield allows the creation of virtually invisible yet strong welds.

TIG welding is most often used where:

- superior quality and clean aesthetics are required;

- thin elements made of aluminum or stainless steel must be joined;

- high control over the welding process is necessary.

This method is especially valued in design, architecture, and high-tech projects.

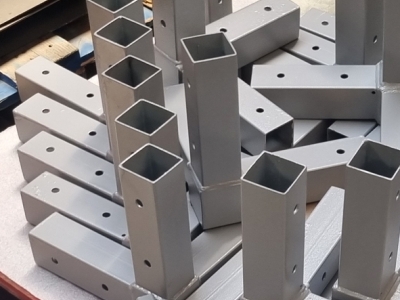

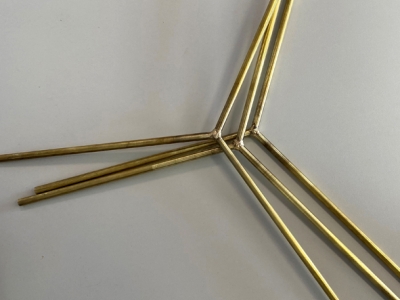

Welding Stainless Steel — MIG and TIG: Two Paths, One Goal

MIG welding of stainless steel and TIG welding are two complementary techniques that together cover a wide range of applications. MIG welding ensures fast and efficient production of stainless steel components, while TIG delivers premium finish quality — even for intricate details.

Depending on the project type, the most suitable method can be selected:

- MIG welding of stainless steel – fast and cost-effective for larger components;

- TIG welding – elegant and precise for small details;

- combined methods – for joining different weld types within one project.

No matter the technique, MIG or TIG stainless steel welding always ensures strong, sealed joints compliant with the EN-1090-1 standard.

Why Choose MIG/MAG and TIG Welding?

MIG, MAG, and TIG welding together cover nearly all modern metalworking needs. From steel structures and aluminum frameworks to decorative stainless steel details — each can be perfectly executed using the right method.

Key benefits of these technologies include:

- versatility — suitable for many different materials;

- durability — strong, load-resistant, and weatherproof joints;

- European standards compliance — ensuring safety and quality.

That’s why MIG, MAG, and TIG welding are the essential tools of every modern metalworking professional.

What Else Do We Offer Besides Welding?

In addition to our MIG, MAG, and TIG welding services, we offer a wide range of other metal and plastic processing solutions. This allows you to complete your entire project in one place — efficiently, quickly, and without the need for multiple contractors.

Explore our additional services:

- Metal fabrication — artistic and functional metalwork solutions;

- Laser cutting of copper — ideal for electrical and decorative components;

- Laser cutting of brass — precise cutting for plaques and detailed parts;

- Laser cutting of aluminum — clean and efficient processing;

- CNC milling of plastics — precise shaping for technical and advertising materials.

Order everything from one manufacturer — save time and budget.

Why Choose Us?

MIG, MAG, and TIG welding are carried out by our experienced team using modern, certified equipment and years of expertise. Our welders are true craftsmen — they understand materials and know how to achieve perfect results. We work in full compliance with the EN-1090-1 standard, guaranteeing quality, safety, and long-lasting performance. Partnering with us means individual attention, on-time delivery, and impeccable finishing. MIG, MAG, or TIG welding? With us — it simply works.