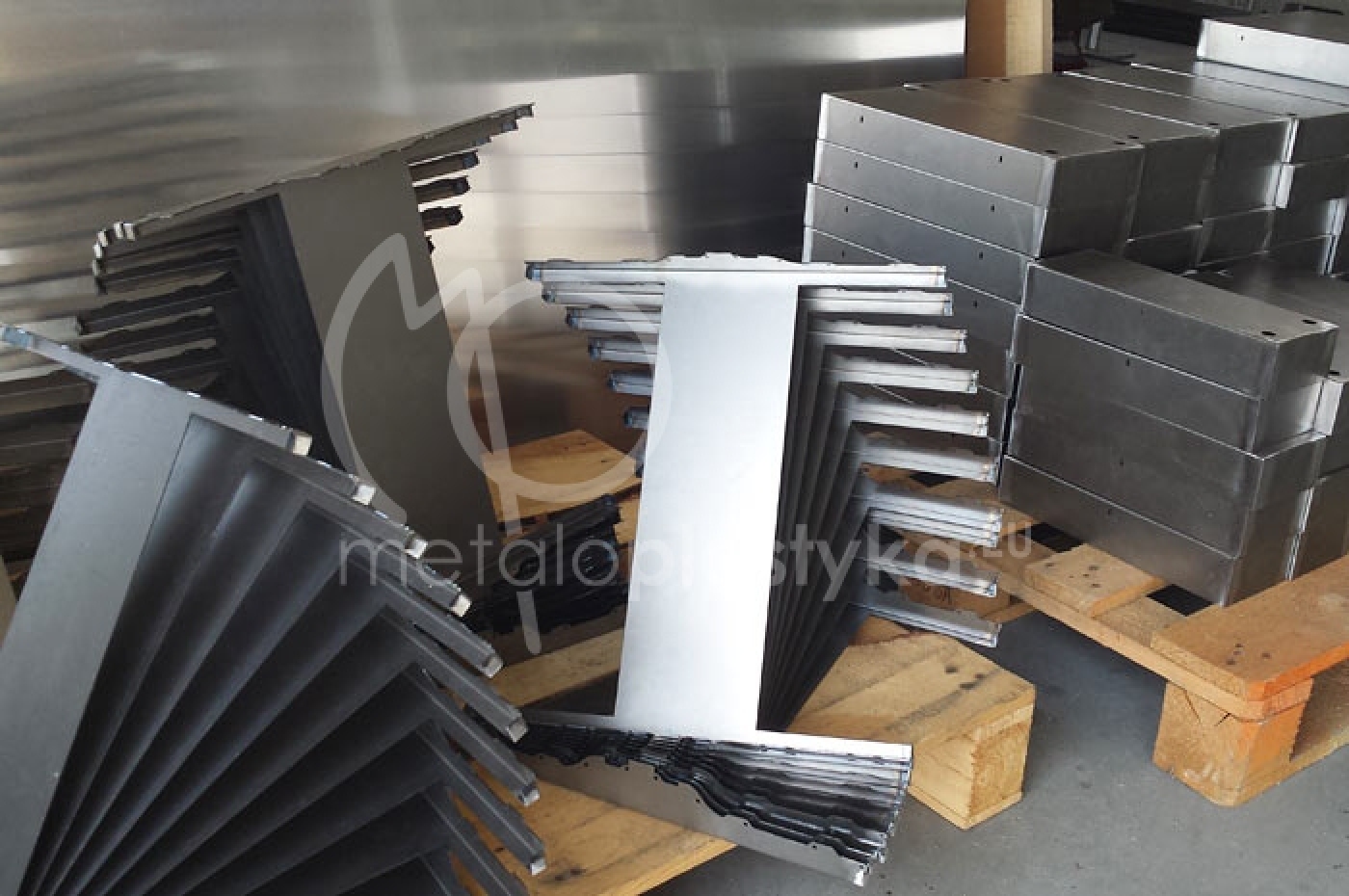

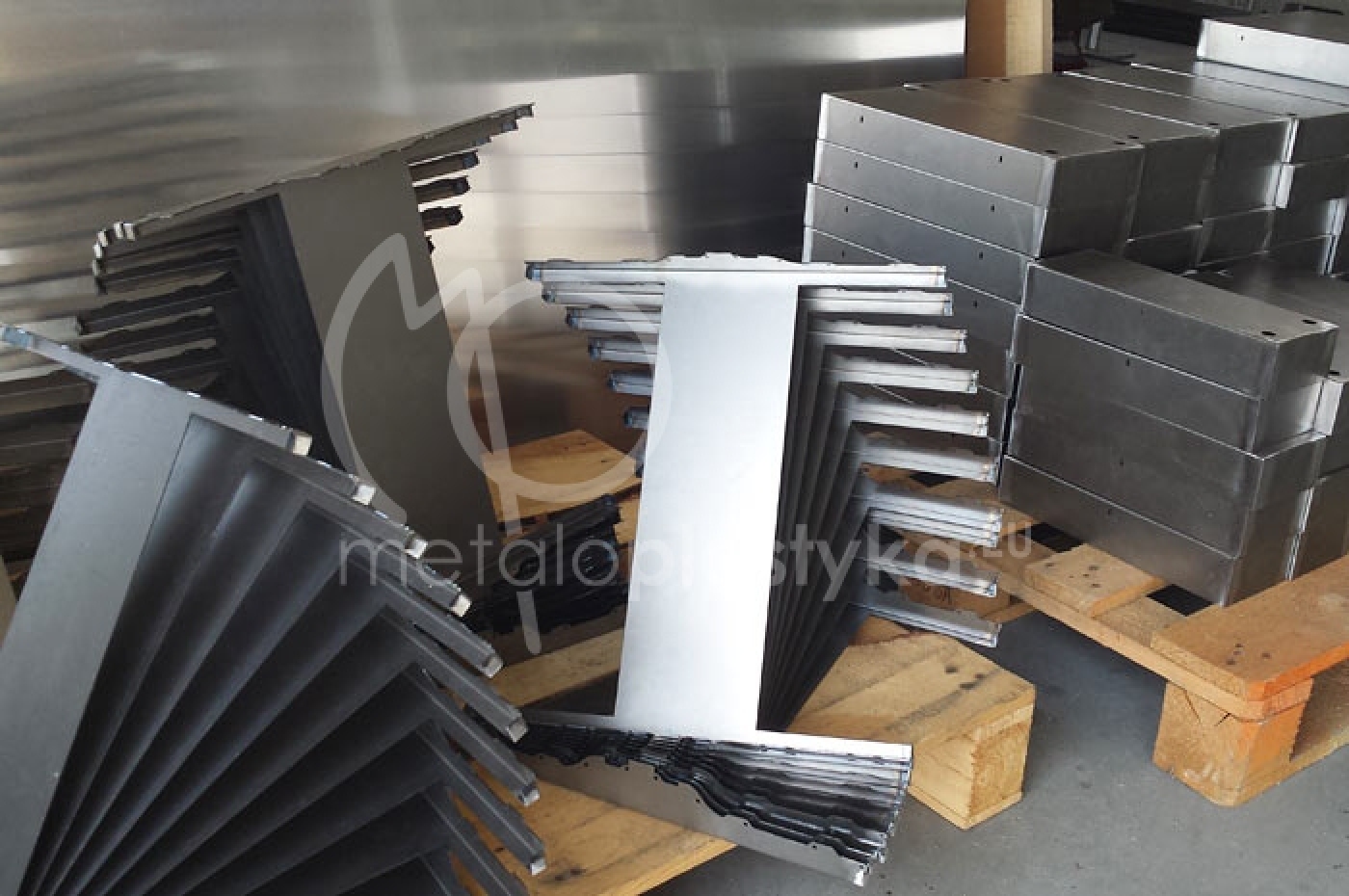

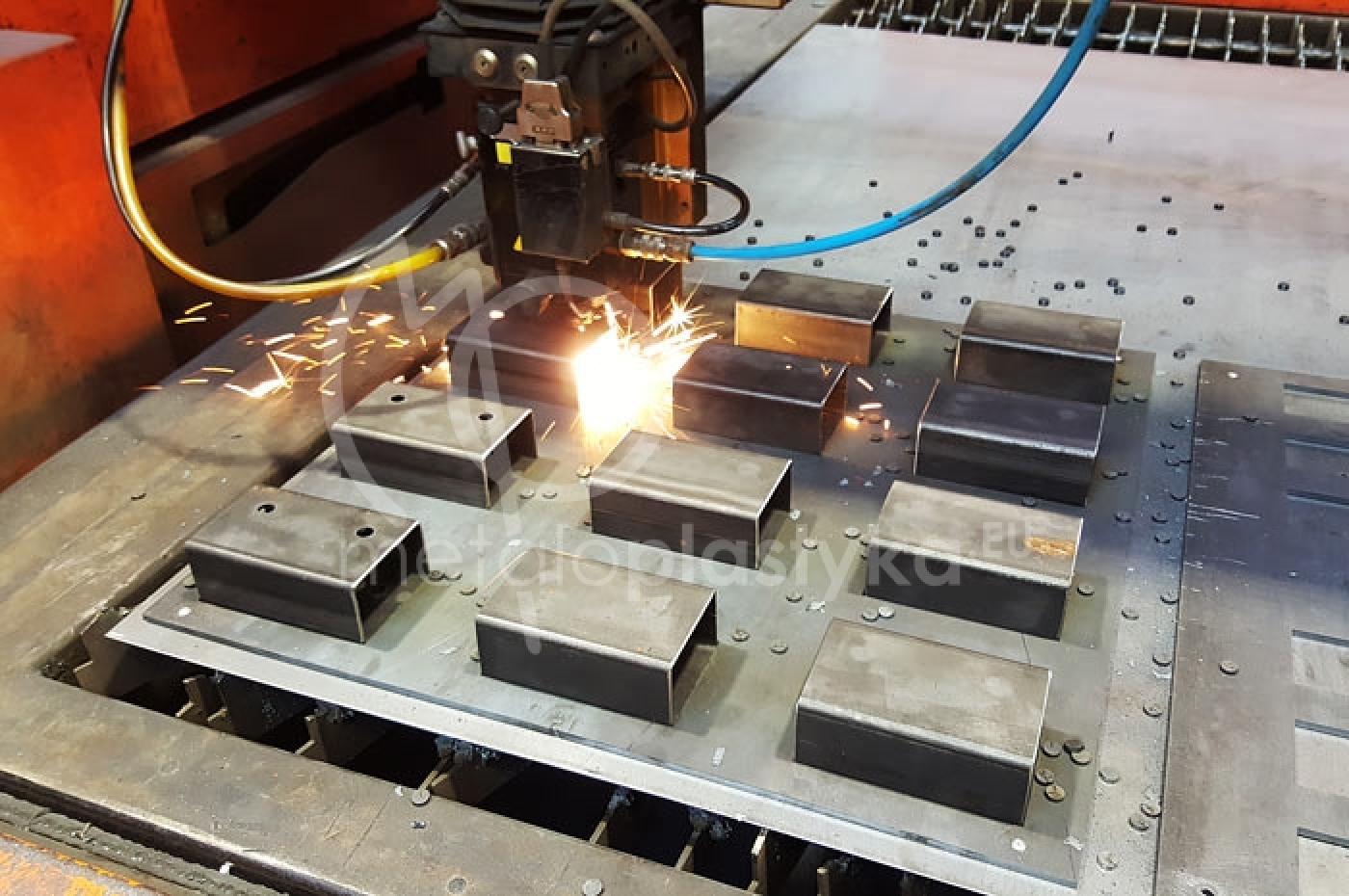

Laser cutting, bending, welding and processing

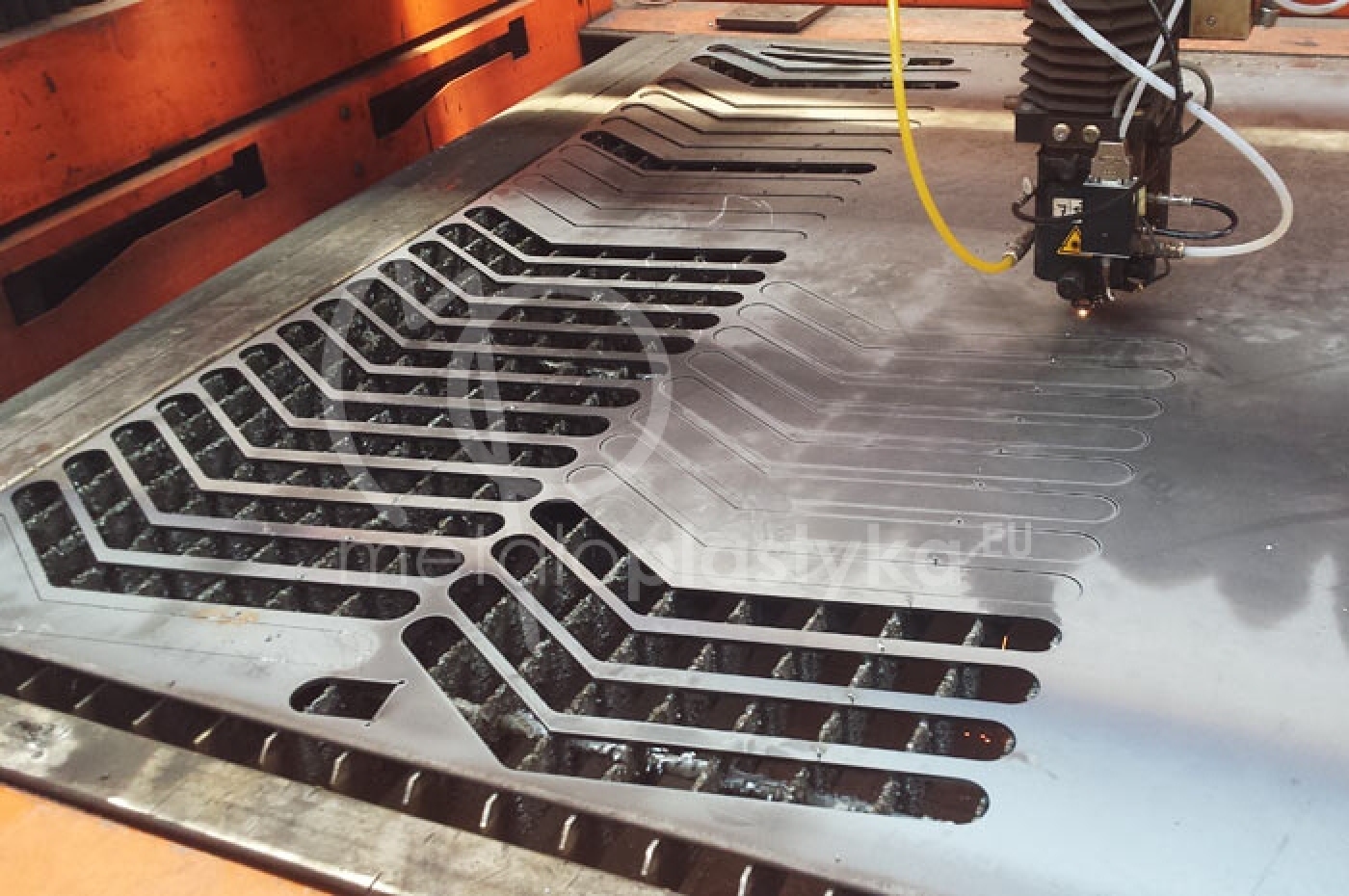

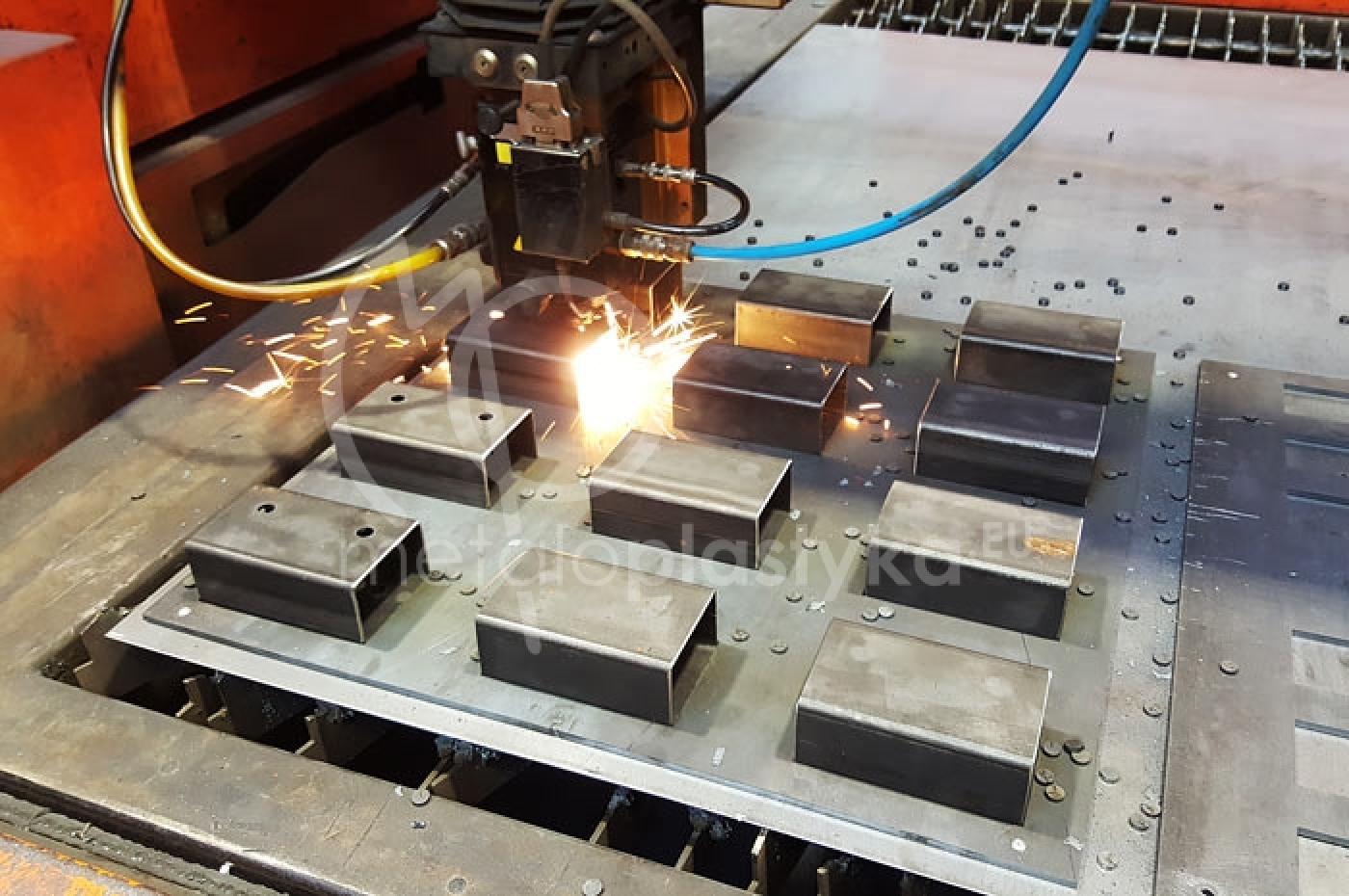

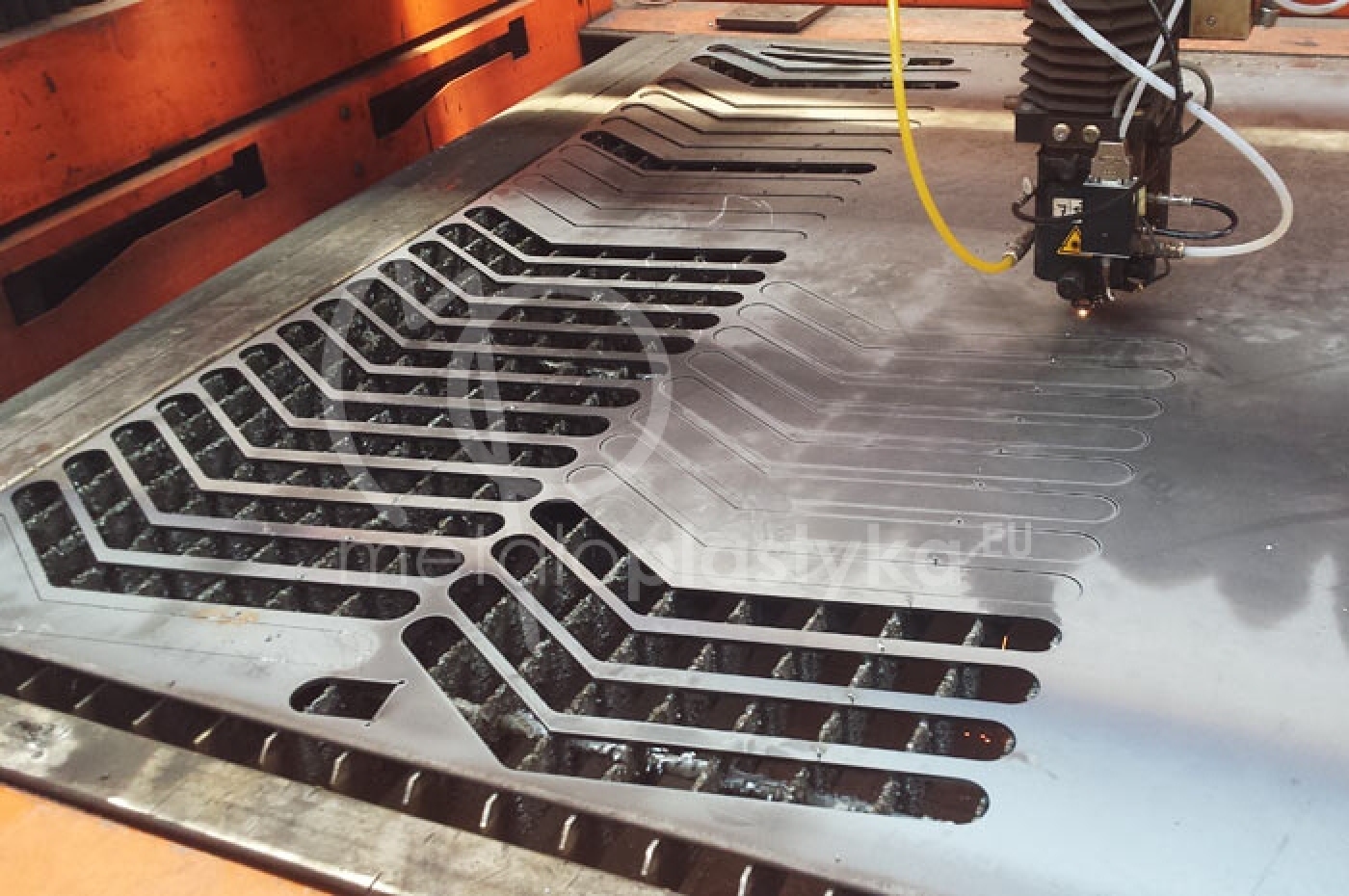

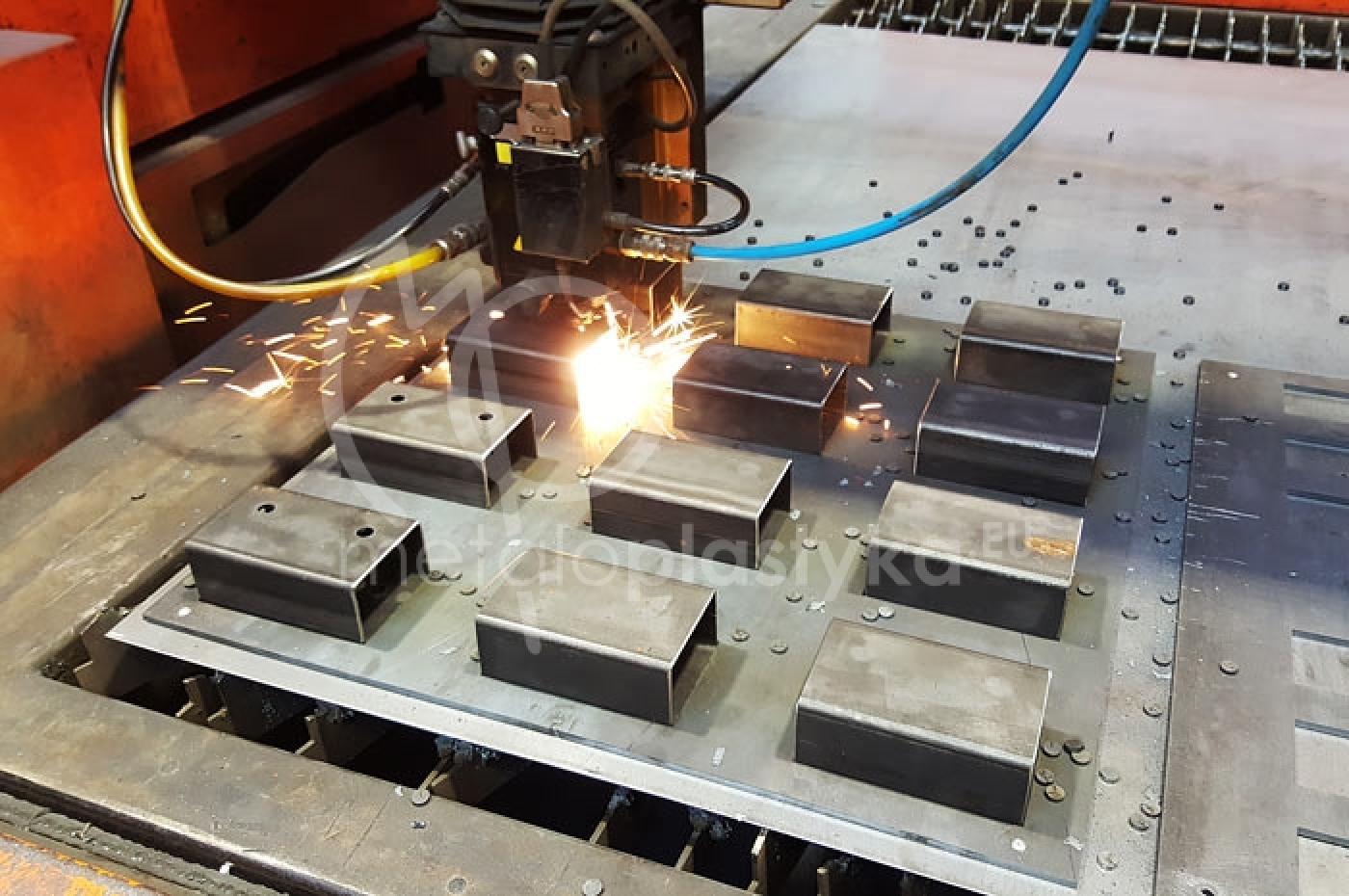

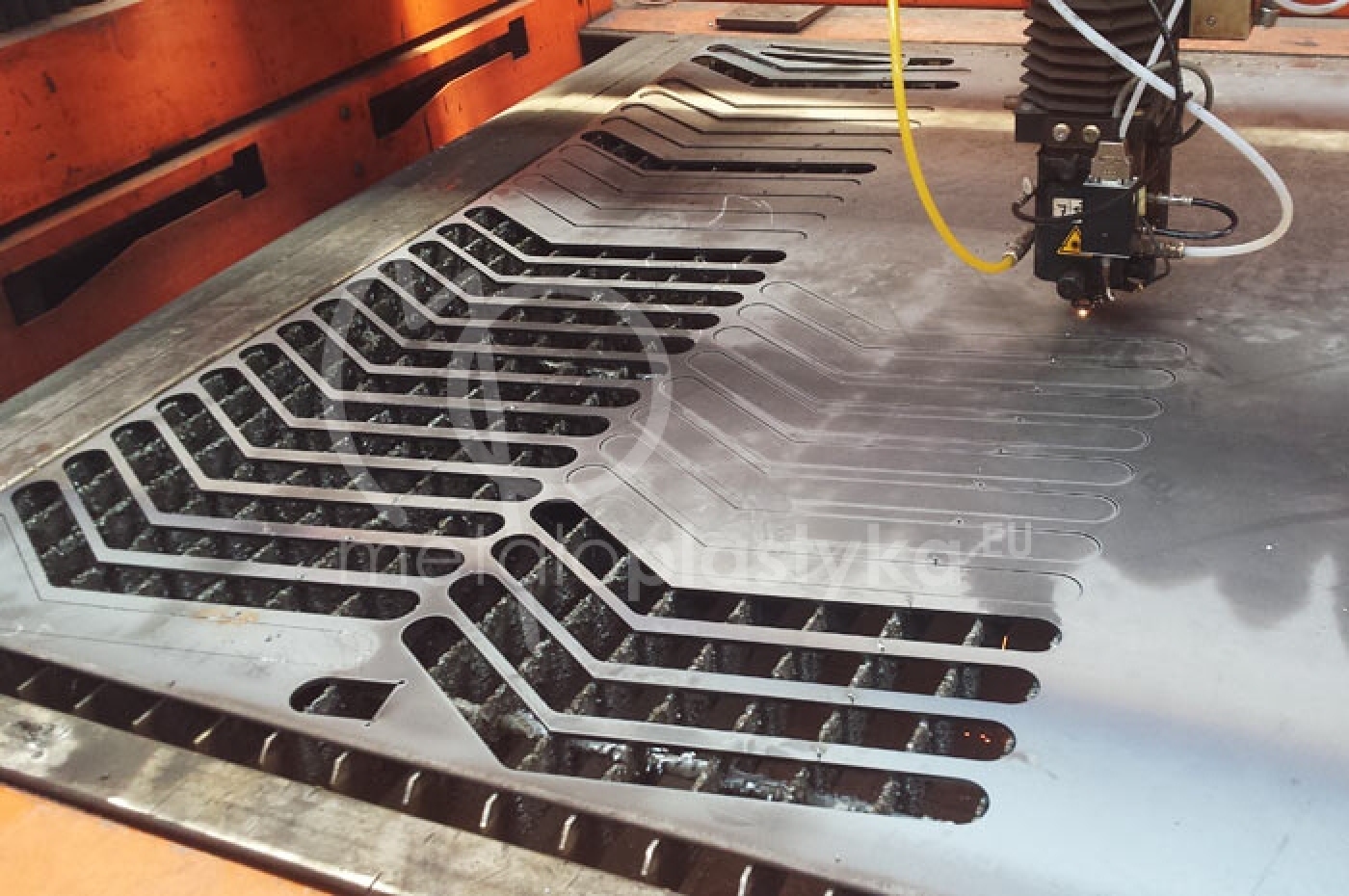

We offer laser cutting services. High quality results obtained with equipment by Bystronic. Max work surface is 1500 x 3000 mm. Laser cutting is used on specific types of steel.

Technology.

Laser cutting comes in two variants:

- Melt and blow

This technique uses pure high-pressure gas to blow molten material from the cutting area, without using the gas in the melting process itself. - Reaction cutting

This technique uses oxygen as cutting gas

Materials that can be used for laser cutting:

- normal steel, black steel (ex. S235, S355)

- stainless steel, glossy, brushed

- acid-resistant steel, glossy, brushed

- tool steel

- electrical steel

- copper

- aluminium

- brass

- spring steel

- molybdenum

- acrylic glass

Advantages of laser cutting:

very fast and economic detail manufacturing (high speed cutting)

high precision

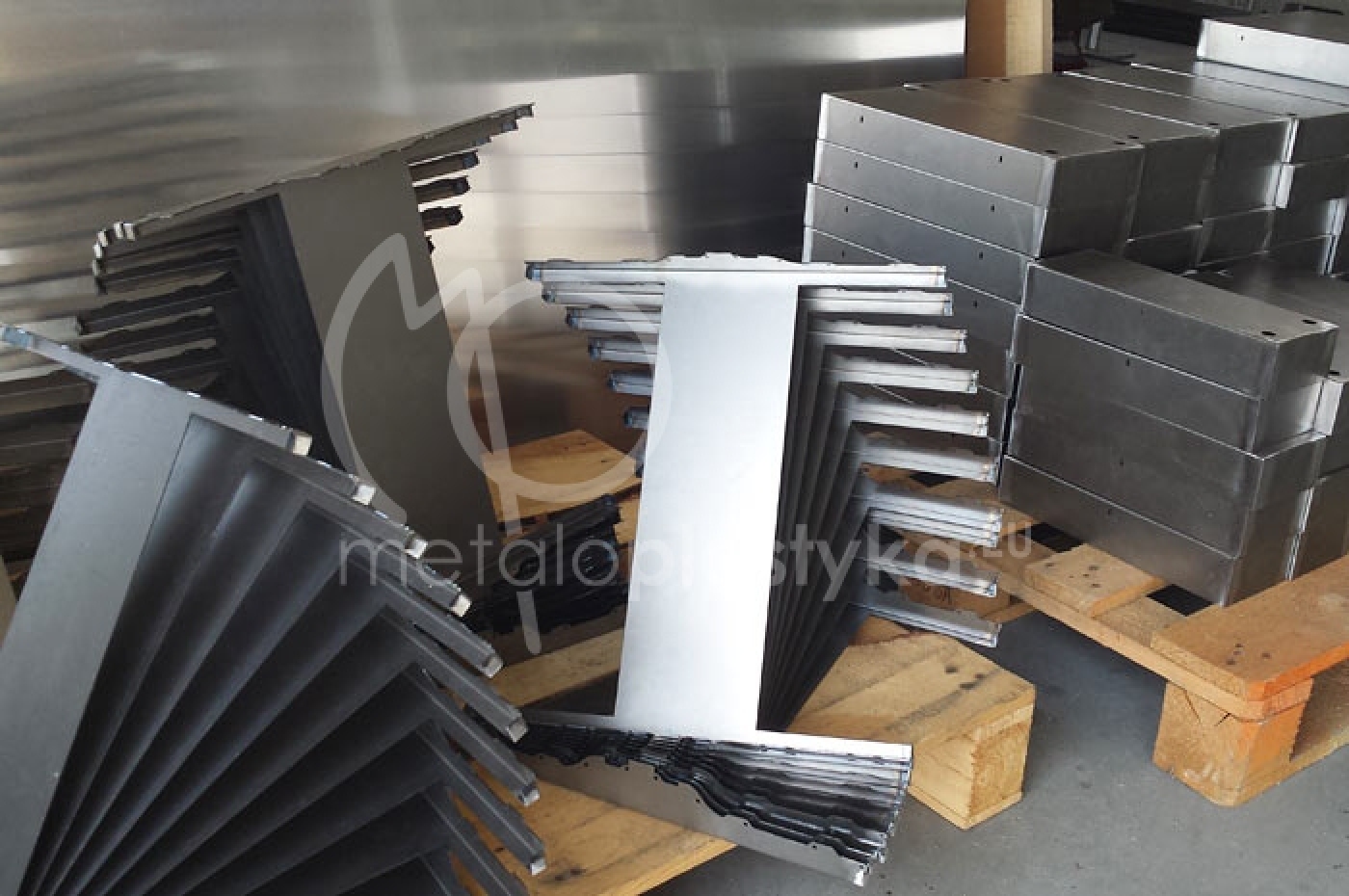

no need for further processing (in most cases)

narrow exposition area (the narrow laser beam means that only a small area of the metal sheet is heated up ? as opposed to plasma cutting for instance ? and does not change the structure or properties of the metal)

high repeatabilty

minimal waste due to digital optimisation of the cutting proces

for big and small series of products (quick implementation)